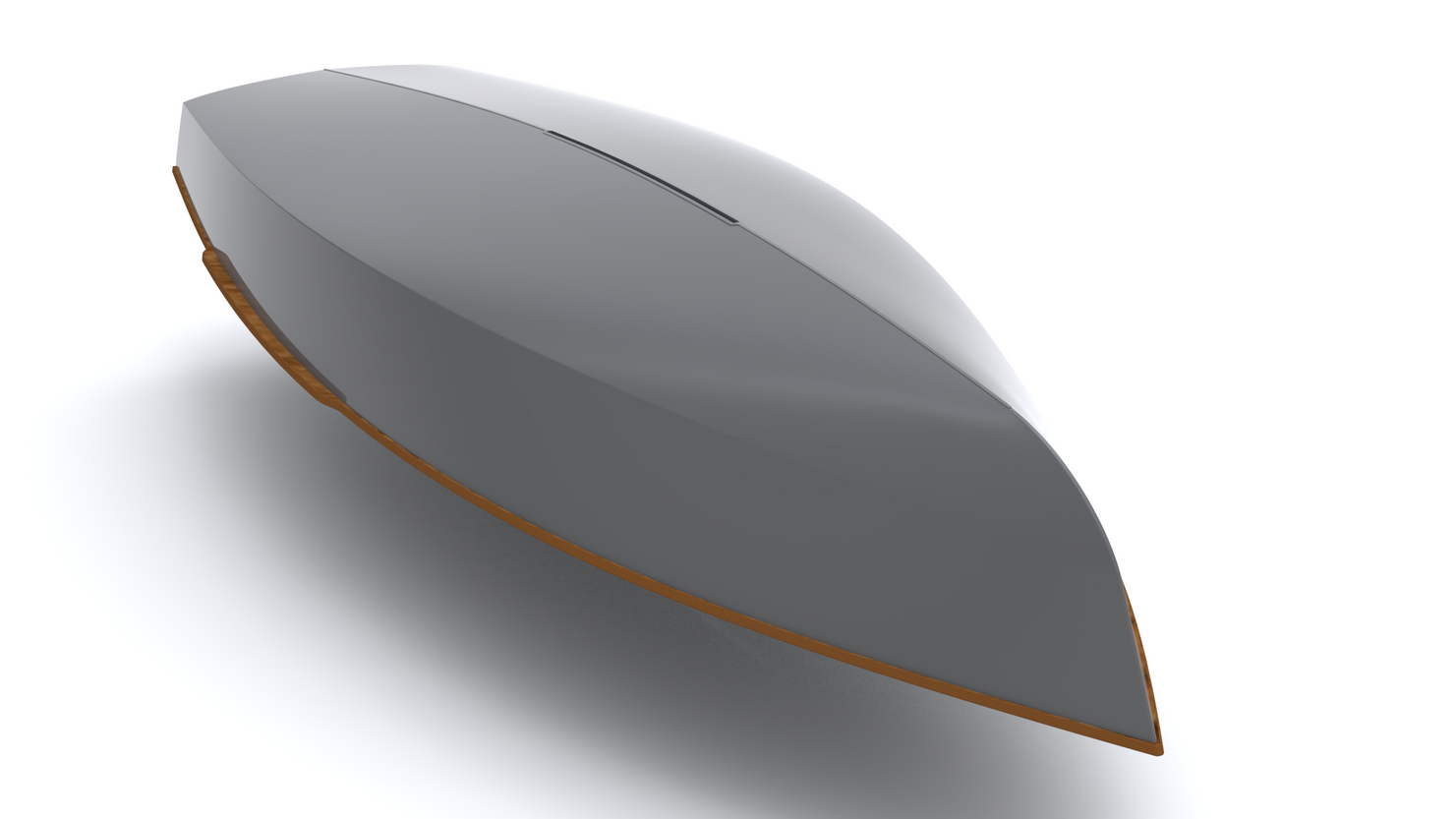

BIG 9.0 OK dinghy

New BIG 9.0

-

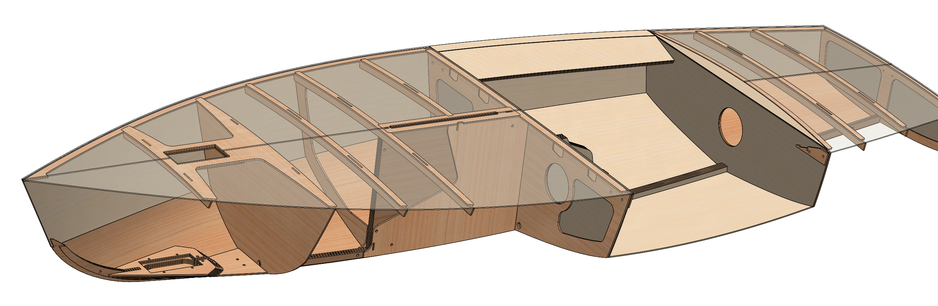

Optimized wood construction for optimal strength and stiffness

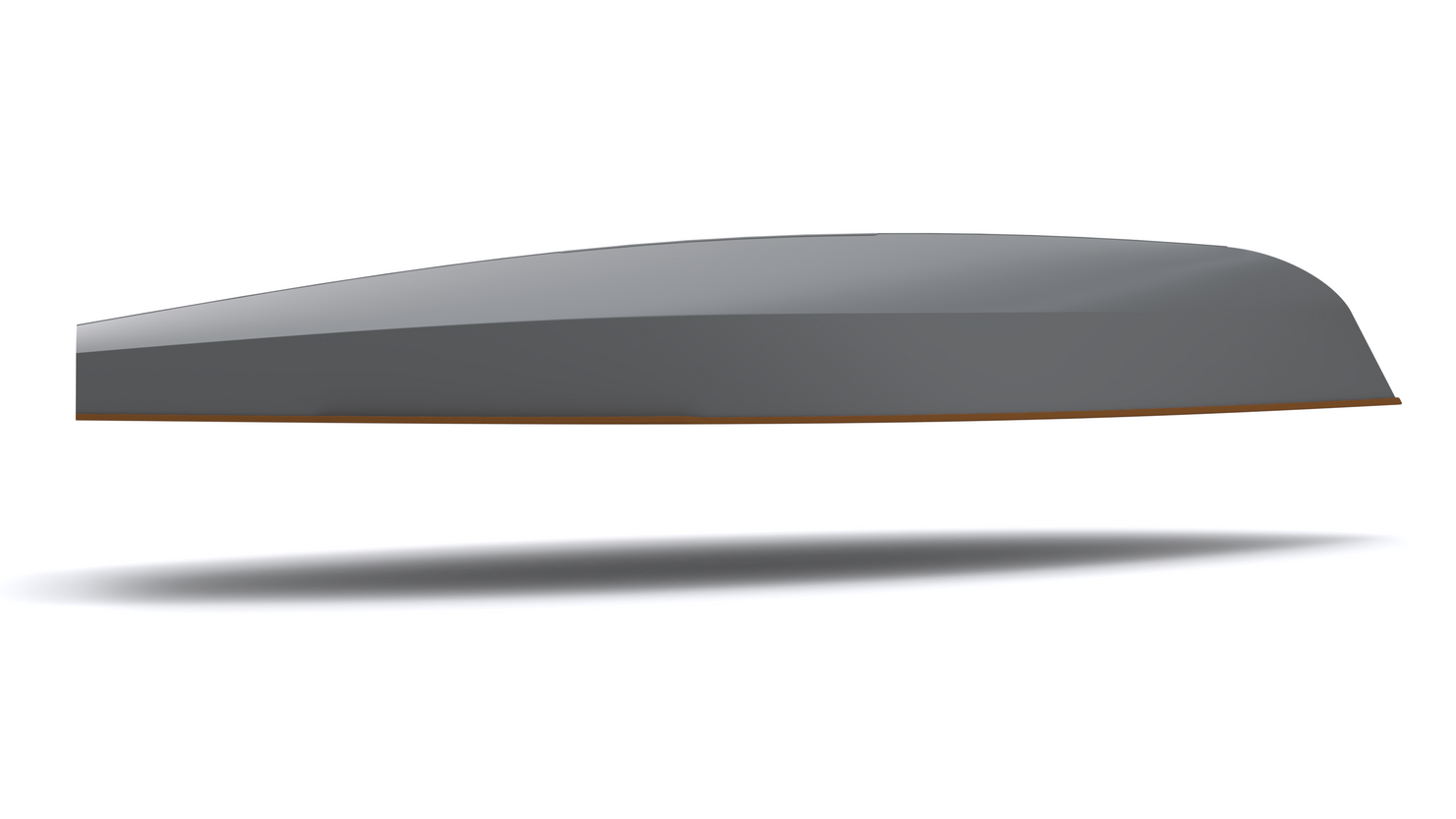

- Hull shape optimized with buoyancy center moved slightly to leeward for more righting moment and upwind performance.

- Slightly fuller bow for more downwind performance

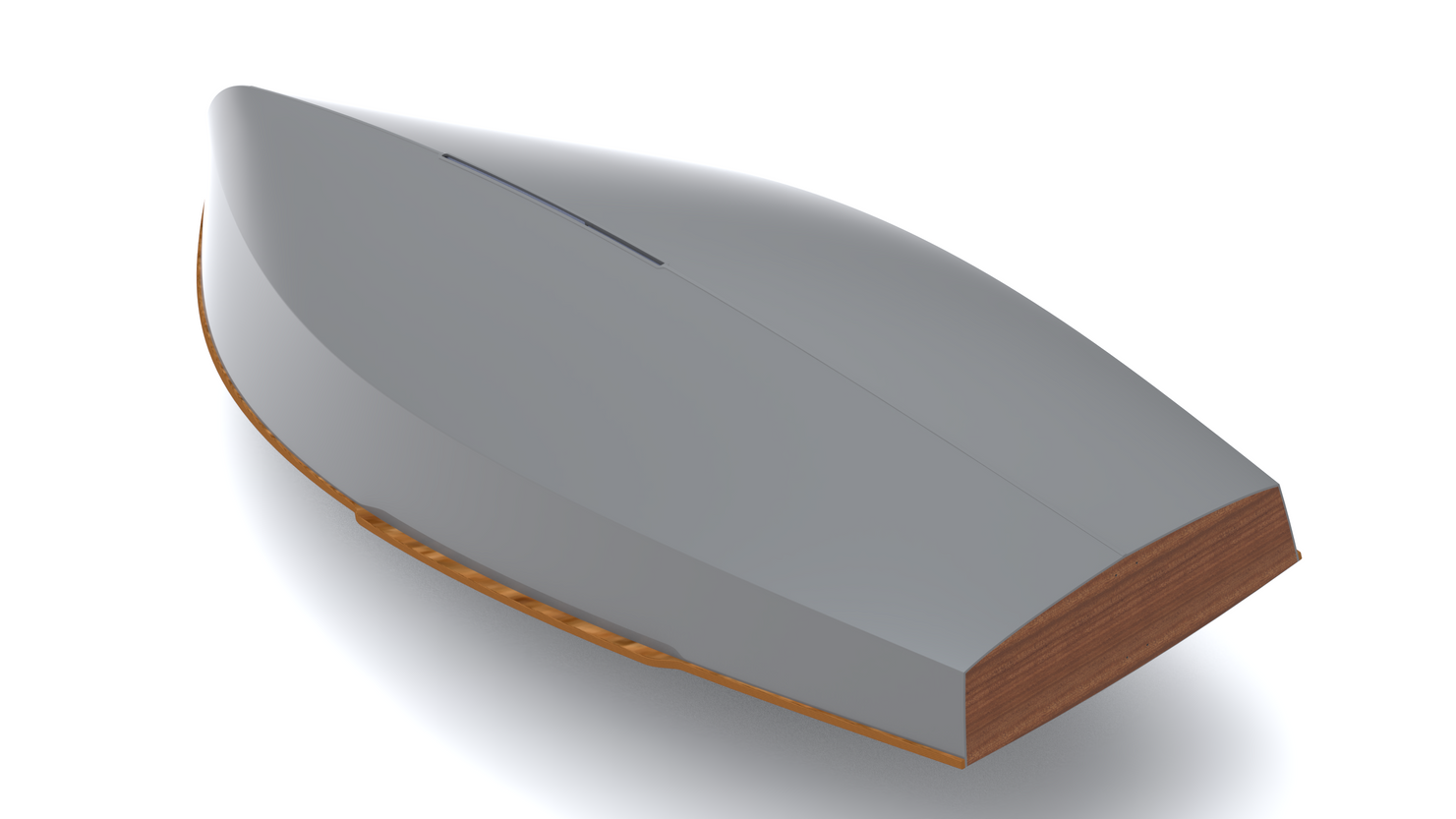

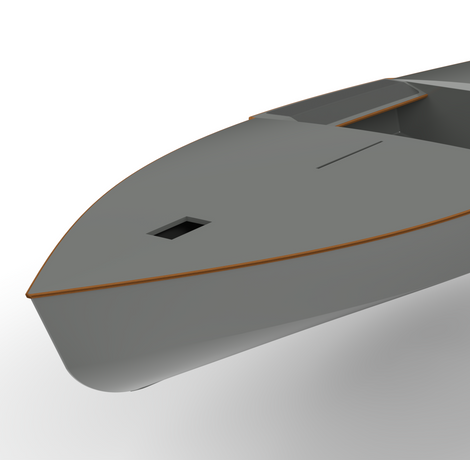

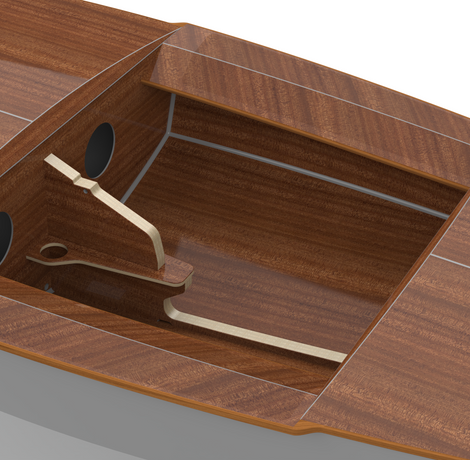

- New ergonomic hiking deck

- Chamfered bulkheads fore and aft for the cockpit

Completely new construction method

The bottom panels, which were previously clamped down in a construction fixture and locked in shape by gluing to the bulkheads and stringers, are now vacuum glued in shape over a plug.

With this technique, a more even and tension-free bottom structure is achieved. As the process is not self-builder friendly. the bottom panels are delivered fully glued from buildaboat.

Optimized weight distribution

The new construction method, with form-glued bottom panels, has meant fewer bulkheads and stringers at the front of the dinghy. Compared to our previous dinghies, the center of gravity has thereby become more centered around the front end of the cockpit.

Build it with a good result

The dinghy is built in a simple construction fixture, this together with the well-constructed kit ensure a problem-free construction process with certainty of a good result.

Foils for a fast hull

The foils are specially designed for the BIG 9.0, a combination of CNC manufactured foam core and epoxy and glass gives ultra light, perfectly shaped and strong foils.

Special fittings

Special fittings CNC manufactured in POM or 3D printed in carbon reinforced nylon.

3 models

With Gaboon/Okoume, Kahya mahogany and Ash

Basic

Manufactured entirely in Gaboon plywood. This model is intended to be painted.

New Nordic

Made with Ash on all surfaces of the deck, inside the cockpit, on the freeboard and on the transom. The hull bottom panels and all structural parts are manufactured in Gaboon plywood.

This model can be made with clear varnish on all ash surfaces and with a painted hull.

Classic