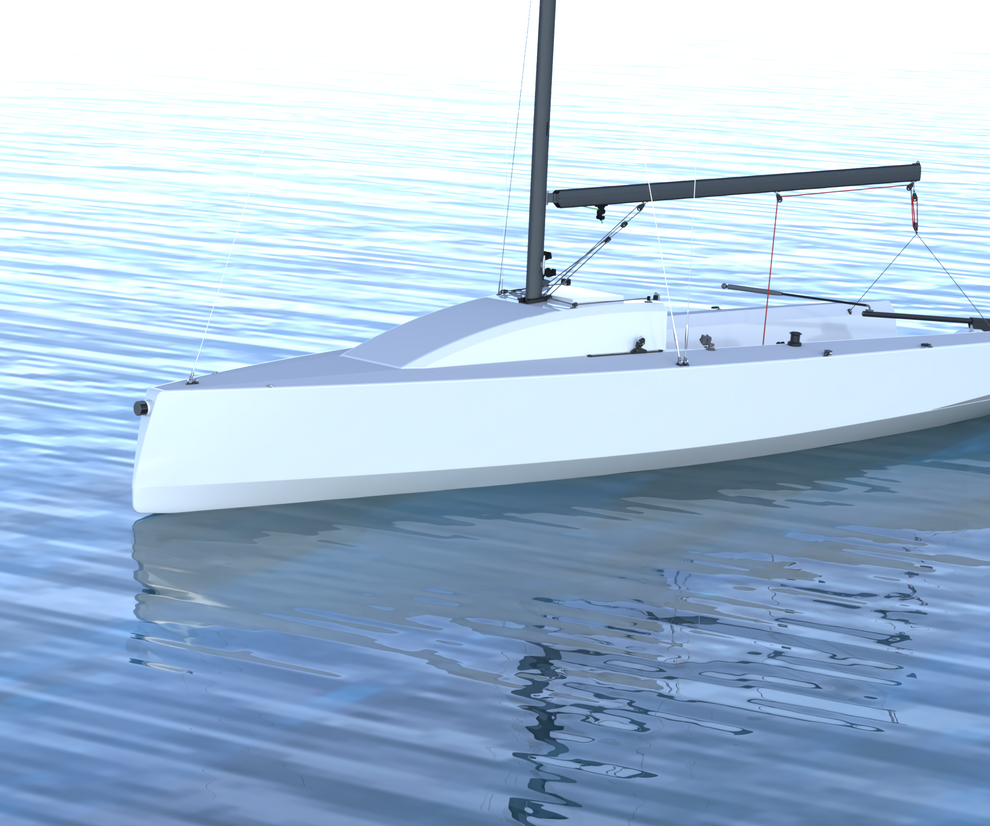

Sportboat

Performance and design

"The new db-22 is a true performance sport boat. The sporty lines keep their promise and give the boat already at a very slight breeze an incomparable feeling af almost weightless gliding"

Fun and fast sailling

"This boat introduces a new dimension of fun and fast sailling in a stable and easy to handle boat"

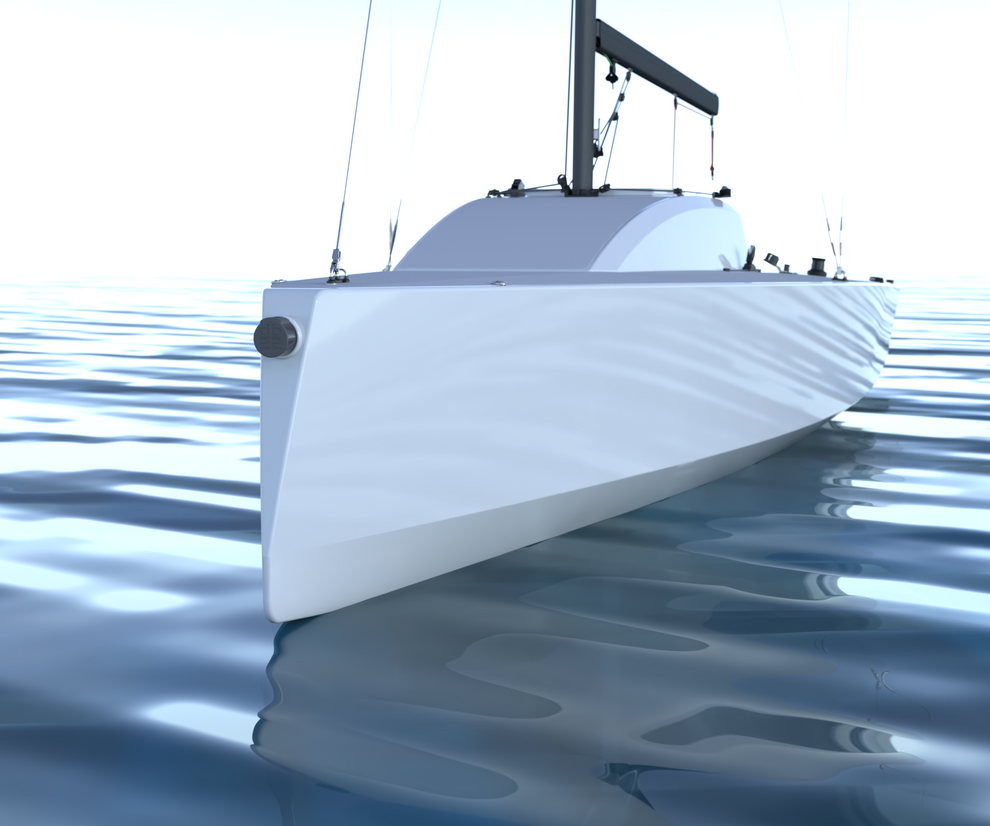

Plywood and epoxy

"The hull for the db-22 is made in epoxy treated marine plywood. This material composition ensures a strong and long-lasting hull.

In less than 300 hours

"the hull is specially designed for home building by non professional, and the accurate CNC machined plywood parts ensure a fast and easy construction process"

A kit or the drawing package

The boat can be built from a ready-made kit or you can buy a digital drawing package and make the kit yourself.

Do you have the skills

To understand the construction and building method, you can start by building a scale model.

Specifications

Dimensions | |

Length (Loa ex. rudder) | :.....................................6.700 M |

Beam (B.Max) | :.....................................2.130 M |

Draft | :.....................................1.650 M |

Weight (displ.) | :.......................................560 kg. |

Keel weight | :.......................................190 kg. |

Construction

- Hull and deck skin in 9-12 mm marine grade plywood, inside panel joining laminated with two layer of 280 gr. glass fabric.

- Bulkheads and stringers in 9-12 mm marine grade plywood, Fillet bonded to hull/deck skin using epoxy resin added high density filler.

- Hull/deck outside surface treated with one layer 280 gr. and 1-2 layers of epoxy resin.

- Hull/deck inside surface treated with 1-2 layers of epoxy resin.

- Daggerboard case in 12 mm marine grade plywood, dagger board bearings, at bottom of daggerboard case, in POM.

- Chain plates and structural fittings bolted to structural bulkheads.

- Bolt, screws, structural fittings and chain plates all in marine grade stainless steel.

- Hull and deck painted with two component polyurethane yacht coating.

- Cockpit sole and deck surfaces painted with two component non-skid polyurethane yacht coating.

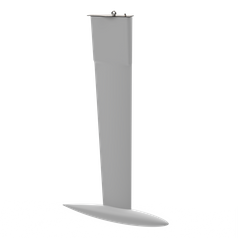

Keel arrangement

- Lifting T-keel

- High aspect dagger board, composite with gelcoat finish.

- 160 kg. lead ballast torpedo.

- Stainless steel safety lock down plate.

- 2 x top to bottom 12 mm stainless steel keel bolts.

- Lifting eye, for keel lifting with crane.

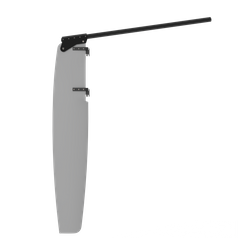

Rudder arrangement

- High aspect transom mounted rudder, composite with gelcoat finish

- Aluminium / Stainless steel gudgeons.

- Aluminium tiller with adjustable tiller extension.

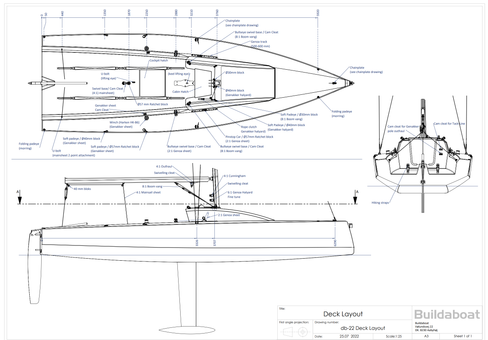

Deck equipment

- one opening hatch of 460mm x 510 mm, aft of daggerboard case.

- Plexiglass access door to cabin.

- Stainless steel U-bolts for shrouds and forestay.

- 4 Flip-up padeyes for mooring/dockline attachment.

- All blocks and cleats form Ronstan or Harken

- Two Harken no6 winches for gennaker sheets.

- Two jib T-tracks with cars and automated ratchet blocks, 2:1 jib sheet leading to cam swivel base.

- 4:1 mainsheet system, automated ratchet block and centerline cam swivel base.

- Two automated ratchet blocks for gennaker sheets.

- Bowsprit launching system/tack line, exiting starboard side of cabin entrance.

- 8:1 vang control leading to two cam swivel bases. Both side of cabin entrance.

- Gennaker halyard clutch starboard side of cabin entrance

- Toe rails with 2 x 2 padded toe straps for hiking and safety.

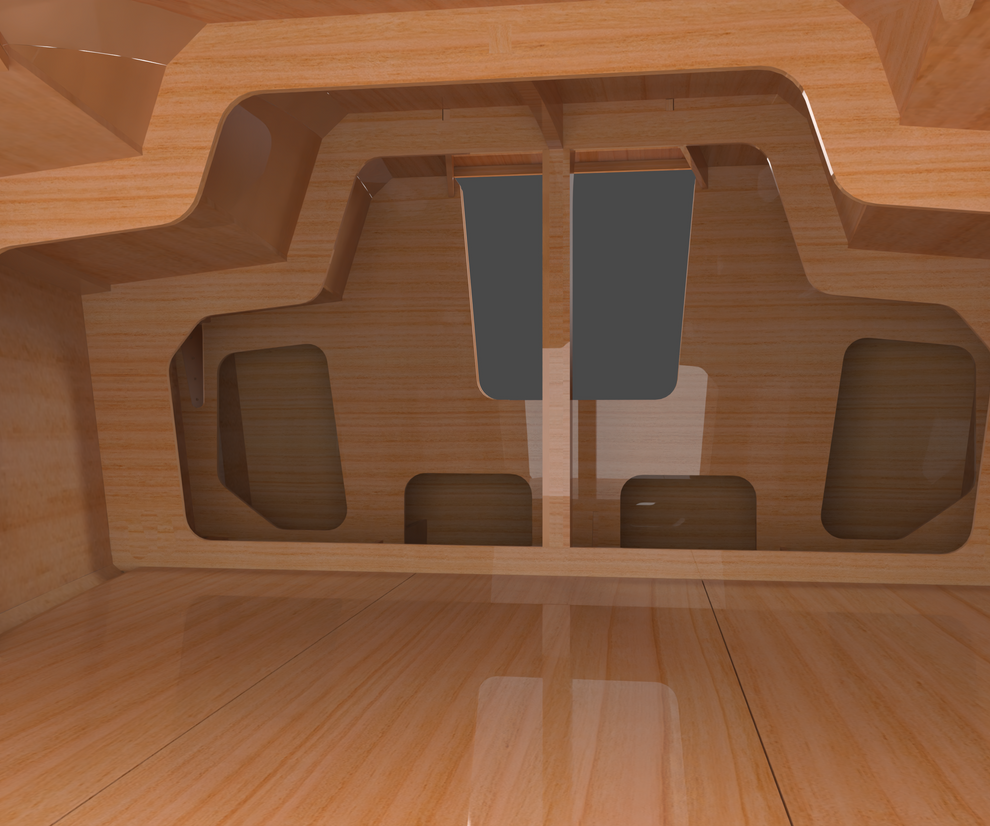

Interior

- Watertight bulkhead aft of daggerboard case.

- Storage room aft of watertight bulkhead, access through aft hatch.

- Cabin with sleeping area and storage below beaths.

Mast & rigging

- Z-Spar Z 190 racing aluminium mast, nature anodized.

- One set of 25 deg. swept back spreaders.

- Hinged mast foot that allows easy setting of the mast without the use of a crane.

- 4-5 mm Dyform standing rigging with Bronze turnbuckles.

- Z-Spar Z-162 racing aluminium boom, nature anodized.

- 4:1 outhaul, pivoting cam cleat between boom vang and mast.

- 5 mm Dyneema jib and mainsail halyards.

- 6 mm Dyneema gennaker halyard, tapered.

- Mainsail halyard cleat port side of mast.

- Jib halyard 4:1 fine tune system with pivoting cam cleat, aft side of mast.

- 3:1 cunningham control with pivoting cam cleat, aft side of mast.

- Retractable aluminium bowsprit controlled from cockpit.

- 8 mm mainsail sheet.

- 6 mm Dyneema jib sheet.

- 6 mm Dyneema gennaker sheet.

Sails | |

Mainsail (5 battens) one reef | :...................................17.50 M2 |

Jib I Light medium (3 battens) | :...................................11.50 M2 |

Gennaker | :...................................40.50 M2 |

Code-0 (optional) | :...................................28.00 M2 |

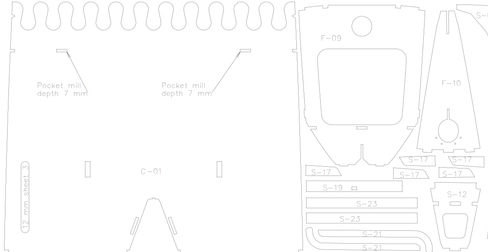

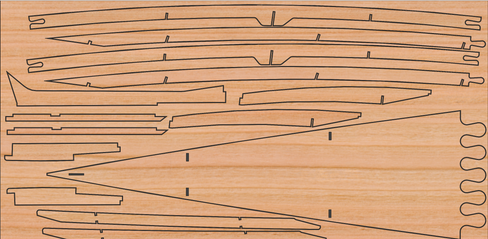

It all starts with a stack of sheets

With all the parts cut out an ready to assembly

The large hull panels that cannot be within the standard format (122x244 cm) are divided into smaller pieces. The panels are assembled with "puzzle joints". these joints are later reinforced with fiberglass.

Each and every joint is made with a mixture of epoxy and filler.

Chine joints are additionally reinforced with fiberglass tape.

All internal surfaces are sealed with 2-3 layers of epoxy.

All the parts are designed to tap together, making it almost impossible to assemble incorrectly

External surfaces are laminated with a layer of 280 gram/m2 fiberglass rowing. this adds strength and robustness to the hull, but most importantly, it seals the plywood against moisture.

A proper surface treatment with epoxy and polyurethane topcoat, gives a strong, light and long-lasting hull.

A boatkit or the drawing package

a ready-made or a do-it-yourself solution

Digital Drawing Package

Our digital drawing package contains CAD data on all individual parts that are needed for you to manufacture a hull construction kit yourself.

drawings on special parts such as chainplates etc. is also included.

All individual parts are nested on 9 and 12 mm "plywood sheets", We use the standard format 1220x2440 mm.

So all you need is to buy some quality marine plywood sheets, and to find a manufacturer who is able to cut the parts either with a milling machine or with a laser.

We use the following formats: DXF, DWG and PDF.

A detailed construction manual is included, here we guide you through the steps of the construction process, how the parts are glued together, surface treatment, choice of epoxy and fiberglass and of course all our tricks.

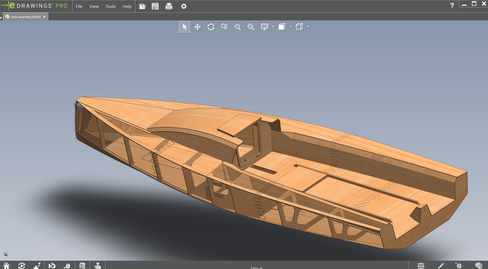

Being able to see the boat virtually in 3D is often a great help, which is why we have included a 3D model. The model can be viewed in the free program "e-drawing" In this program it is possible to measure, make cut views, and to "click" the various pars on and off, to see the construction behind.

Plans included:

- Hull assembly

- Deck layout

- Keel plan

- Rudder plan

- Sail and rig plan

Buying the Digital Pacakage, include a license to build one boat.

Our digital package is the obvious choice if you don't live near Denmark. Overseas shipping is expensive and not environmentally friendly.

Plywood hull kit

Get started quickly with a complete wooden db-22 hull kit, here everything is cut out and ready to assemble.

Our db-22 kit comes in a pack consisting of: 12 sheets of 9 mm plywood and 11 sheets of 12 mm plywood.

In total, the kit consists of 141 individual plywood parts and 9 stainless steel parts (chainplates).

For our building kits we use only the best quality Okume/Gaboon marine plywood.

As with our digital drawing package, detailed construction manual and a 3D "e-drawing" model are included.

Plans included:

- Hull assembly

- Deck layout

- Keel plan

- Rudder plan

- Sail and rig plan

Buying the Plywood hull kit, include a license to build one boat.

What about all the rest ?

more than the hull is needed before you are ready to sail

Keel and rudder

Buildaboat are able to deliver a complete ready-made keel and rudder.

the keel shaft is molded in fiberglass and the torpedo is in lead. The rudder blade is also molded in fiberglass.

Keel blade and rudder blade are both molded using vacuum infused technology.

Are you more interested in making the keel and rudder yourself? We have made a package with drawings, cut-files and descriptions of how you can make these parts yourself in plywood/glass fiber and epoxy.

The keel torpedo must be sand cast in lead. our drawing package contains, drawings and descriptions of how you can make the plug used for this process.

Please find the keel and rudder options in our shop

Mast, rigging and sails

We are happy to supply the mast and sails for your db-22.

We sell masts and rigging from Z-Spars / Hansen Harmacher and sails from Ullman Sails.

Contact us for an offer

Equipment

At buildaboat, we sell all the good brands in boat fittings.

Not all of our products can be found on our webshop.

Contact us if you want an offer for an equipment package for your boat.

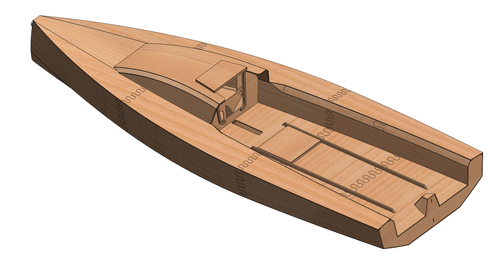

Understand the construction

Pratice by building the study model

Study model

We have produced a scaled-down version of the db-22 hull, which we call the study model.

The model is a 13% scale of the boat and contains most of the parts included in the real hull.

With this model, you get an understanding of the order in which and how the various parts are put together.

Are you curious about the construction and would you like to learn more about the assembly method etc. then the Study model is a good place to start your boat building career.

You will find the study model in our Webshop.